In the world of electronics, the COB Character LCD is transforming project development. It stands out for its compact size and efficiency. Dr. Alex Morgan, an industry expert, once stated, "The COB Character LCD offers unparalleled versatility for designers." This statement resonates in today's rapid tech advancements.

Integrating COB Character LCD into your project can elevate user engagement. Designers often appreciate its clear visibility and reduced power consumption. Imagine creating a user interface that is not only functional but visually appealing. However, not all projects come out perfect. It’s essential to iterate and test your designs, ensuring the display functions seamlessly.

While exploring possibilities with the COB Character LCD, keep in mind the learning curve. Every project presents unique challenges. Embrace these hurdles, as they can lead to innovative solutions. Balancing creativity and practicality is key. A thoughtful approach is crucial for harnessing the true potential of this technology.

COB (Chip On Board) Character LCD technology has gained popularity in various projects. It offers a compact design, making it ideal for limited spaces. The technology involves mounting the display chip directly onto the circuit board. This method improves performance and reduces production costs. Users often find installation straightforward. However, some face challenges with orientation and wiring.

One major benefit of COB LCDs is their energy efficiency. They consume less power, which is crucial for battery-operated devices. These displays can show clear text and simple graphics. The readability in different lighting conditions is another advantage. Still, not all projects require such displays. Sometimes using them can feel excessive.

Users should consider the specific needs of their projects. Are the text clarity and size adequate? Will the chosen display fit within the design constraints? Answers to these questions can help refine decisions. Designing with COB LCDs might seem easy. Yet, it requires ongoing evaluation and adjustments. Many projects benefit from the insights gained during development.

| Feature | Details | Benefits | Applications |

|---|---|---|---|

| Display Type | COB (Chip-On-Board) Character LCD | Compact design, space-saving | Consumer electronics, industrial equipment |

| Dimensions | Various sizes available (e.g., 16x2, 20x4) | Flexible size options for different projects | Embedded systems, prototypes |

| Power Consumption | Low power operation | Energy-efficient for portable devices | Wearable technology, battery-operated devices |

| Viewing Angle | Wide viewing angle | Improved readability from various angles | User interfaces, dashboard displays |

| Interface | Typically parallel or I2C | Easy to integrate with microcontrollers | Microcontrollers, Arduino projects |

The COB character LCD modules are vital for many electronic projects. Key specifications to consider include display size, resolution, and power consumption. Most modules range from 16x2 to 20x4 in size. The resolution typically involves 5x8 dots for each character. This makes them suitable for displaying alphanumeric data clearly.

Power consumption is another crucial aspect. COB character LCDs often operate at a low voltage of around 5V. Reports indicate that their energy efficiency can reach up to 80%. This allows for extended battery life in portable devices. Additionally, many models feature a backlight option, enhancing visibility in low-light environments.

Tips: Always evaluate your project needs. Ensure the display size matches your design. Keep the power requirements in check to avoid excess energy use. Remember, the wrong size or high power can lead to project failures. Thoughtful planning in these areas will streamline your project. Also, consider that not all COB modules are easy to interface with different microcontrollers. Testing is essential before finalizing your choice.

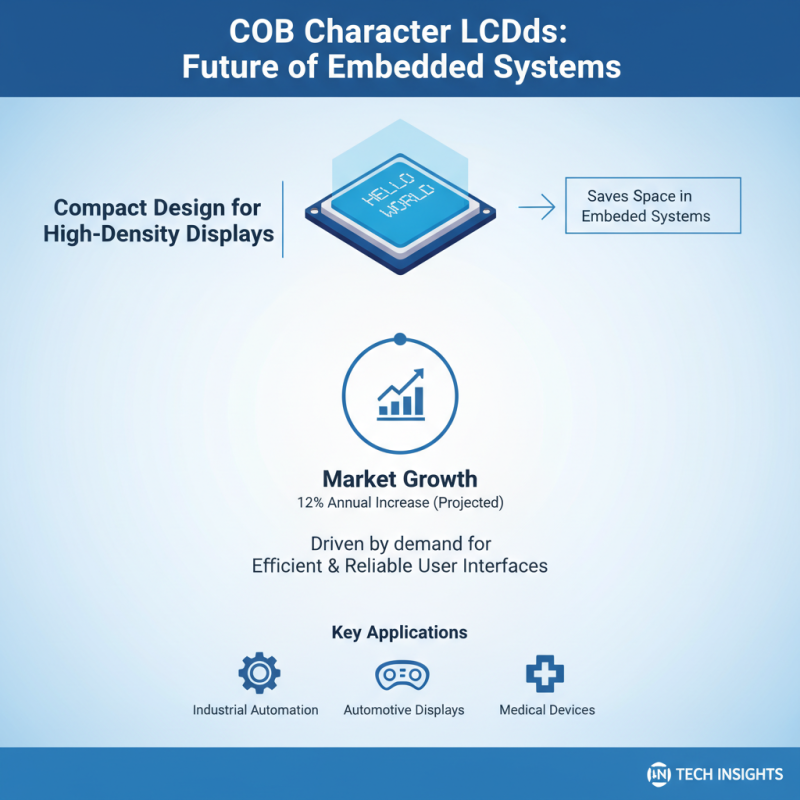

COB (Chip-On-Board) character LCDs are becoming a staple in embedded systems. Their compact design allows for high-density displays in limited space. According to recent market analysis, the demand for such displays is expected to grow by 12% annually. This trend reflects the need for efficient and reliable user interfaces in various devices.

Integrating COB character LCDs into projects requires careful consideration of design and layout. Factors like power supply and communication protocols are crucial. For instance, using I2C or SPI interfaces can greatly enhance communication efficiency. Many engineers overlook these details, leading to performance issues. The integration process also demands precise soldering techniques; poor connections can hinder display functionality.

User experience plays a vital role too. Brightness, contrast, and refresh rates must be tested rigorously. It’s not unusual for prototypes to fall short in these areas. Therefore, engineers should spend time refining their designs. Early-stage testing is an invaluable tool that can prevent future headaches. Monitoring feedback during development stages is essential to adapt to user needs and preferences.

Using COB character LCDs in your next project can be rewarding, yet challenging. These displays are compact and energy-efficient, making them ideal for various applications. However, programming them requires attention to detail. According to industry research, developers often face hurdles in optimizing display clarity and performance.

When working with COB LCDs, ensure you focus on character mapping. Corrections can be tedious, but accurate mapping is crucial. A small error can lead to distorted outputs. Use clear labeling for each character in your code. This practice aids troubleshooting later and enhances readability.

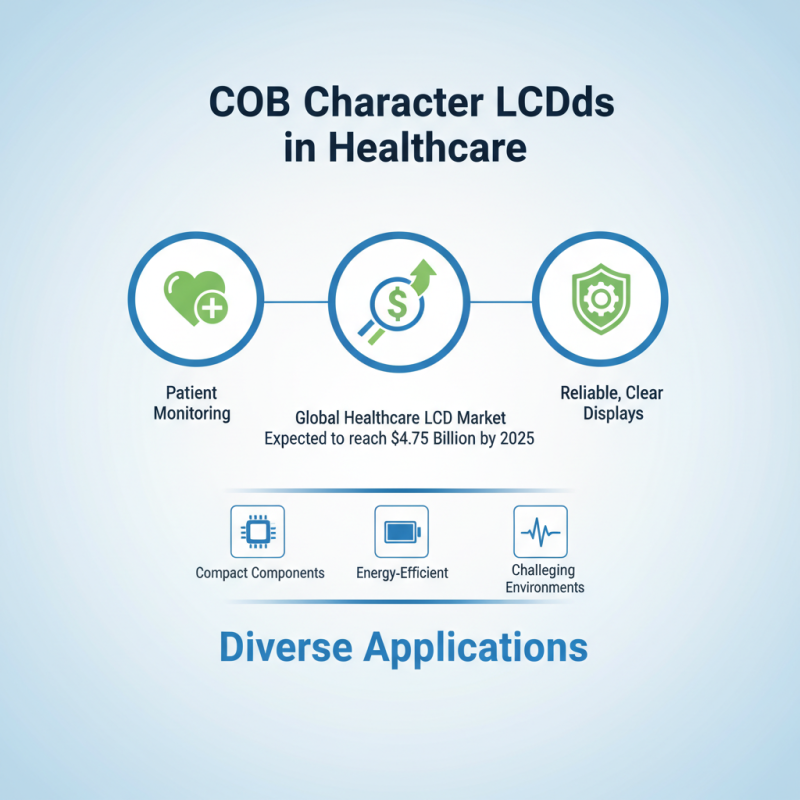

COB character LCDs have found diverse applications across various industries. In healthcare, these displays are often seen in patient monitoring systems. A study by MarketsandMarkets noted that the global healthcare LCD market is expected to reach $4.75 billion by 2025. This growth is driven by the need for reliable, clear displays that can operate in challenging environments. Many medical devices require compact and energy-efficient components. COB character LCDs meet these demands effectively.

In the automotive industry, COB character LCDs are also on the rise. They provide critical information to drivers, from speed to navigation. According to a report by Research and Markets, the automotive display market is projected to grow significantly. The need for better readability in various lighting conditions boosts COB LCD adoption. However, integrating these displays into existing vehicle designs is often complex and requires thoughtful engineering.

Despite their advantages, challenges remain. For instance, temperature fluctuations can affect display performance. Additionally, COB character LCDs may not have the same color range as other display technologies. These limitations can restrict creativity in design. As industries continue to innovate, finding solutions to these issues will be vital for maximizing the potential of COB character LCDs.