In the rapidly evolving world of electronic displays, the COB Character LCD stands out for its efficiency and versatility. COB, or Chip-On-Board technology, integrates an LCD panel directly onto a circuit board. This design reduces the size of displays while enhancing durability, making them ideal for various applications. According to recent industry reports, the global market for character LCDs is expected to reach $2.4 billion by 2025.

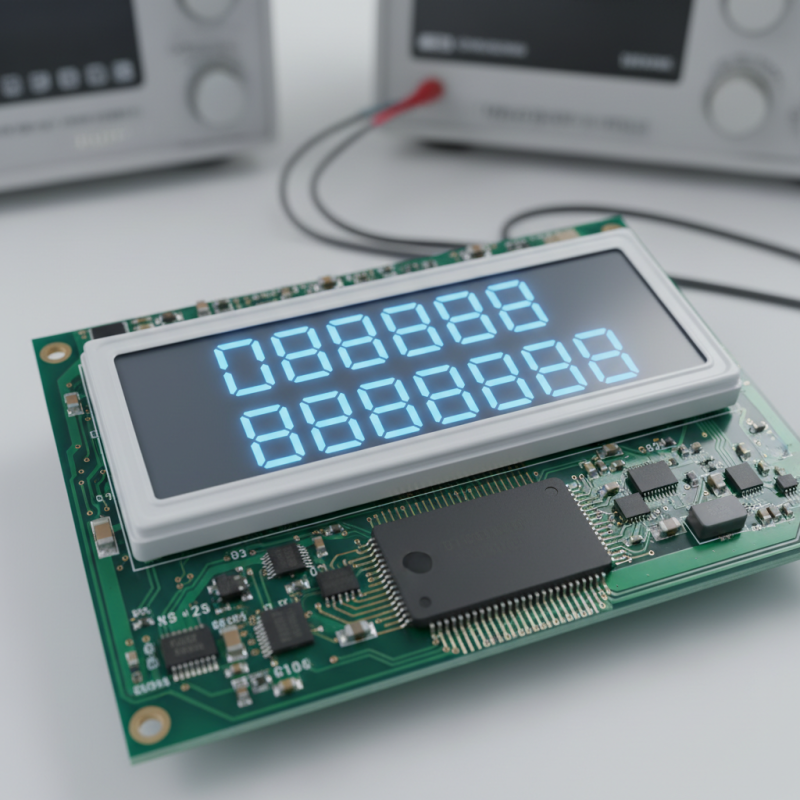

The use of COB Character LCDs is prevalent in devices like calculators, appliances, and automotive dashboards. This technology allows for compact designs without sacrificing performance. However, the integration process can lead to challenges. There may be variability in manufacturing quality, which can impact display clarity. Fluctuating material costs also pose a threat to pricing stability.

As user demands shift towards more advanced displays, manufacturers face pressure to innovate. The challenge lies in balancing cost-effectiveness with high-quality production. While COB Character LCDs offer myriad advantages, companies must continually reassess their goals in this competitive sector.

The COB (Chip on Board) Character LCD represents a significant leap in display technology. It integrates the driver IC directly onto the LCD panel, saving space and reducing component count. This integration leads to a thinner design, making it ideal for compact devices. The simple wiring contributes to a cleaner layout as well. As devices become smaller, the COB design gains importance in many applications.

One of the notable benefits of COB Character LCDs is their improved reliability. Fewer connections mean fewer points of failure. The durability of these displays is a plus for applications in challenging environments. However, the manufacturing process can be more complex than traditional LCDs. The need for precision can lead to increased costs, and not all designs benefit equally.

Ultimately, the significance of COB Character LCDs lies in their compact form factor and reliability. They support a wide range of applications in consumer electronics, automotive, and industrial devices. Yet, designers must weigh the advantages against the potential costs and complexities involved. Striking a balance in design choices remains crucial.

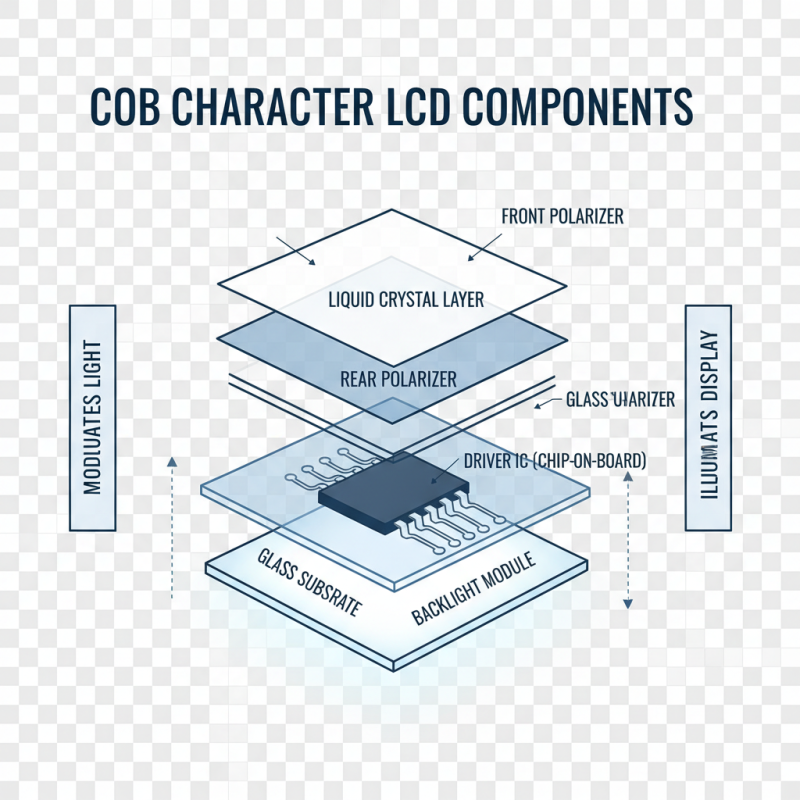

COB character LCDs are widely used in various electronic devices. They consist of several components that work together to display characters. The main part is the liquid crystal layer. This layer modulates light to create images on the screen. It sits between two polarizers, which help manage light. The backlight illuminates the display from behind, enhancing visibility.

The structure of a COB character LCD also includes a controller chip. This chip processes input signals and translates them into visual content. It connects directly to the LCD, allowing for compact designs. Additionally, the printed circuit board is crucial for wiring. It provides electrical connections for the display to communicate with other components.

However, the assembly process can sometimes be flawed. Misalignment during manufacturing may lead to display issues. Dust or debris can impact clarity. These imperfections remind us that precision is vital. Creating high-quality displays is not always straightforward. Each element must be carefully calibrated for optimal performance. This complexity reflects the challenges engineers face in producing reliable technology.

COB (Chip-on-Board) character LCDs are fascinating devices used in various applications. They generate images through a straightforward process. Each display consists of numerous segments, creating the characters and symbols seen on the screen. These segments light up individually. A controller sends signals to activate specific segments based on the required character. The segments use liquid crystals to control light, offering clear visuals.

Tips: Ensure proper wiring when setting up the display. Faulty connections can lead to inconsistent performance. Testing multiple configurations might be necessary.

The technology behind COB LCDs relies on applying voltage. When voltage is applied, liquid crystals align, allowing light to pass through or block it. This change in state enables the characters to be visible. It’s crucial to understand that temperature can affect performance. Lower temperatures may slow down response times.

Additionally, environmental factors play a significant role. Humidity and light exposure can lead to issues. A more controlled environment can improve longevity and visibility. Regular maintenance is essential to ensure these displays operate optimally over time.

COB character LCDs, or chip-on-board character liquid crystal displays, are widely used in consumer electronics and industrial applications. Their compact design allows for more efficient use of space. This is crucial in devices like handheld gadgets and appliances. Many industrial machines also rely on these displays for status monitoring. The clarity of text on these screens helps in user interaction.

In consumer electronics, COB character LCDs are often found in devices like digital thermometers and kitchen scales. Their low power consumption makes them ideal for battery-operated devices. However, their brightness can be a concern in bright environments. Adjustments might be needed to improve visibility. In industrial settings, they are featured in control panels. Operators appreciate the straightforward text readout, but sometimes the limited graphics can lead to confusion.

Despite their advantages, there are drawbacks. For instance, display size is often fixed. This can limit customization for specific applications. Users may find themselves wishing for more flexibility. As technology evolves, addressing these issues will be important for future designs. Understanding both the strengths and weaknesses can lead to better implementations of COB character LCDs.

COB (Chip On Board) character LCDs offer unique advantages over traditional LCD technologies. With a compact design, COB LCDs directly bond the display chip to the circuit board. This results in a thinner profile and reduced space requirements. In contrast, other LCDs may use additional layers, leading to a bulkier appearance.

In terms of market performance, COB LCDs are increasingly favored for their lower manufacturing costs. This makes them an attractive option for budget-conscious projects. However, they may come with trade-offs. Some users report that color accuracy can be less precise compared to other technologies. This is worth considering for applications requiring high fidelity.

Tip: When selecting an LCD, assess your specific needs first. Clarity and size matter. Don't just go for the cheapest option. Another tip: test various models before making a decision. There can be significant differences in performance. Regular feedback from users helps refine choices over time. Always prioritize quality over cost.